As outdoor activities increase, the sales of travel tents are also gradually increasing. Seeking a comfortable and luxurious experience outdoors is what most people pursue nowadays. Newxon, as an outdoor equipment manufacturer, is constantly striving for customer experience and continuously improving. It actively adopts new materials, new technologies, and new processes in its products to improve the deep processing technology of its products and produce gorgeous and practical outdoor products. In our tent products, the fabrics are also carefully selected. Each product has strict standards for fabrics. Therefore, Newxon has accumulated rich experience in the selection of fabrics.

Introduction to tent fabrics

Requirements

Since tents are required to be portable and easy to carry, their base fabric is made of lightweight fabrics. At the same time, since the fabric is in a covered or suspended state during use and must withstand various tensions from metal supports, ropes, etc., the fabric must have a large strength. In addition, tent fabrics must also have good waterproof and breathable capabilities. In general, the requirements for tent fabrics are as follows: windproof, breathable, vapor permeable, good water resistance and water repellency, sun-resistant, weather-resistant, good color fastness, mold and moth-proof. High-end tents also require flame retardancy and resistance to ultraviolet radiation. In terms of pattern design and color, they also need to be fashionable and beautiful.

Introduction to textile fabrics

In order to adapt to different temperature environments, tents have different structures such as single-layer, double-layer, and triple-layer. The advantage of a single layer is that it is lightweight, economical, small in size, and relatively simple in manufacturing technology. The difference between a double layer and a single layer is that an additional layer of breathable inner tent is added to the design to mainly solve the problem of water condensation on the inner wall of a single-layer tent. Because in cooler seasons, the heat emitted by the human body will condense water droplets on the inner wall of the tent under the action of cold air outside the tent. The accumulated water will flow down along the inner wall of the tent and wet the sleeping bag. After adding an inner tent, the outer tent is not directly connected to the bottom of the inner tent. The heat emitted by the human body passes through the inner tent and condenses on the outer tent. The water droplets can flow directly to the ground. The design of a triple-layer tent is to add a layer of cotton tent inside the inner tent to further increase the warmth effect. This type of triple-layer tent can be used in an environment of minus 10 degrees Celsius, and the temperature inside the tent can rise to around 0°C. The outer tent is the protective layer of the tent and is the main force for rain protection. It has a high density. Generally, the outer tent of a tent is a fabric with waterproof and breathable functions. Considering the dimensional stability, breaking strength and other special finishing requirements of tent fabrics, nylon and polyester filament plain weave fabrics are mainly used, and a small amount of other thin fabrics such as cotton and polyester/cotton cloth are also selected. The fabric density has a greater impact on the finishing effect of tent fabrics.

Post-finishing

Post-finishing required for fabrics Generally, tent fabrics are required to undergo water-repellent and coating finishing, but high-end fabrics often require other special finishing treatments, such as anti-ultraviolet, water and oil repellent, and flame retardant finishing.

Coating finishing

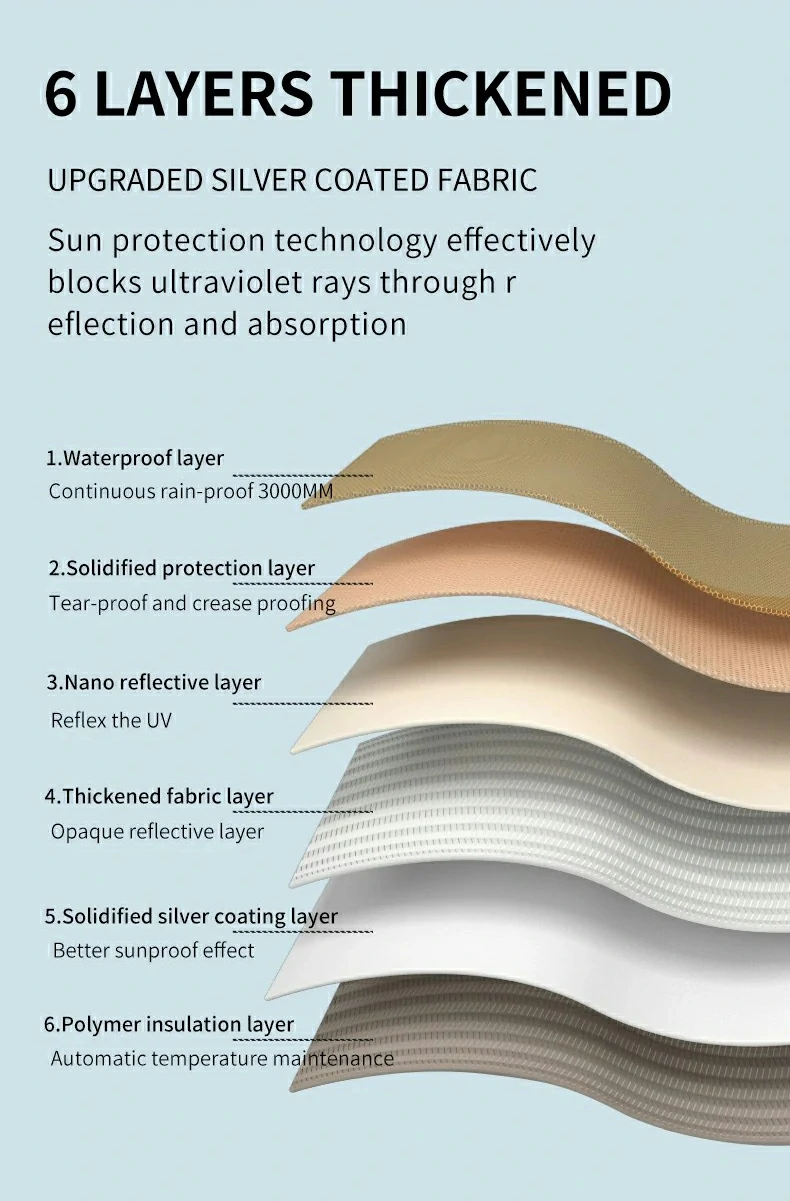

The finishing of tent fabrics for water resistance and other properties is mostly achieved through coating. At present, polyurethane coating agents are ideal coating agents for tent fabrics. Their characteristics are good elasticity, wear resistance, high temperature resistance and good bending and stretching resistance. The coating strength is high and suitable for thin coatings and high water pressure coatings. Most tent fabrics now use polyurethane coatings. Refer to this product.

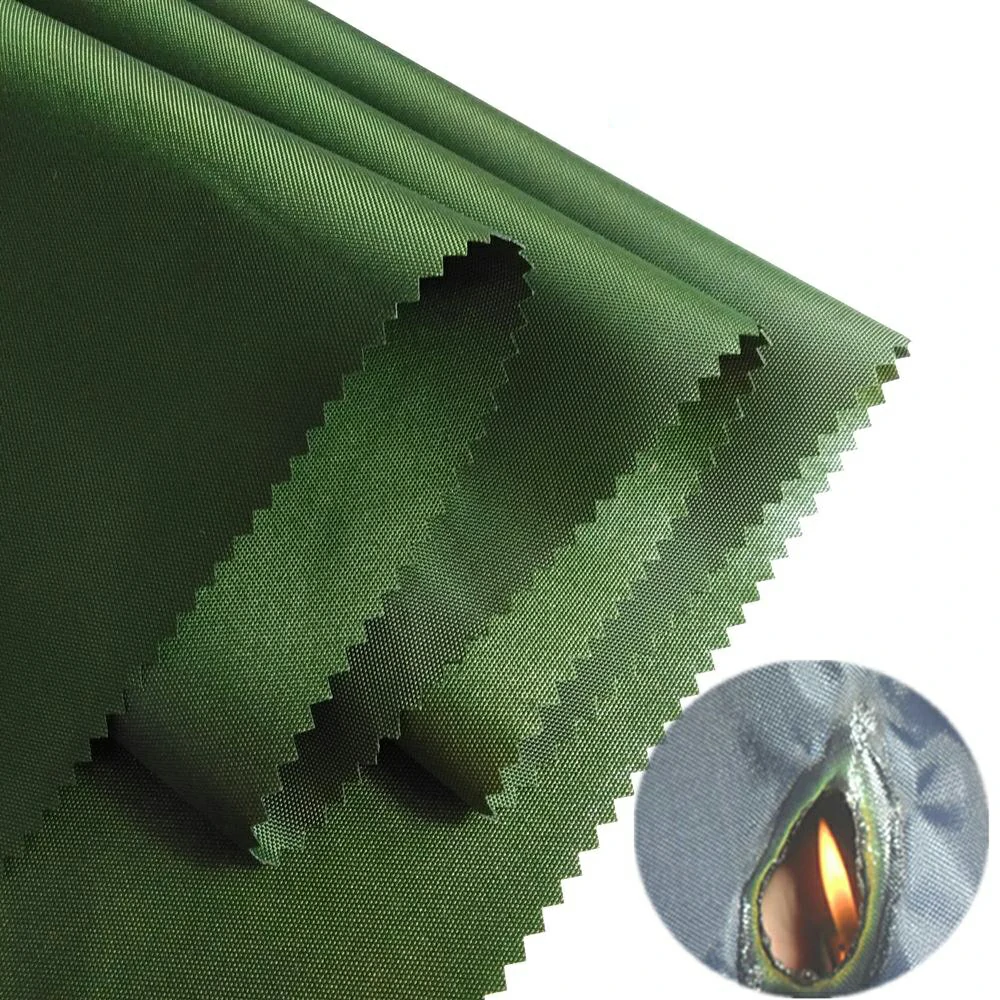

Flame retardant finishing

The flame retardancy of tent fabrics is usually achieved through two processes: impregnation and coating. Newxon can also meet the flame retardant requirements of OEM & ODM products for customers.

Anti-ultraviolet finishing

Ultraviolet rays accelerate the aging of textile fabrics and the fading of dyed surfaces in sunlight. Since tents are often exposed to strong sunlight, many sellers have put forward requirements for anti-ultraviolet finishing of tent fabrics. At present, products are generally processed and produced according to the requirements of tent sellers.

Other finishing

According to different usage scenarios and needs, in addition to the above finishing treatments, tent fabrics are often required to undergo special post-finishing treatments such as anti-mold and antibacterial, anti-static, etc.

Based on the above experience, we strictly design high-quality products in accordance with standards during the product update process to win the appreciation and trust of customers. Click to view our products.

Newxon Outdoors, where luxury meets the wilderness.